apsint code is generally divided into groups of number like: XX XX. XXXX. XXX-XXX/XXX

EXAMPLE: 19 8. 600. 35- Rs2/Tz

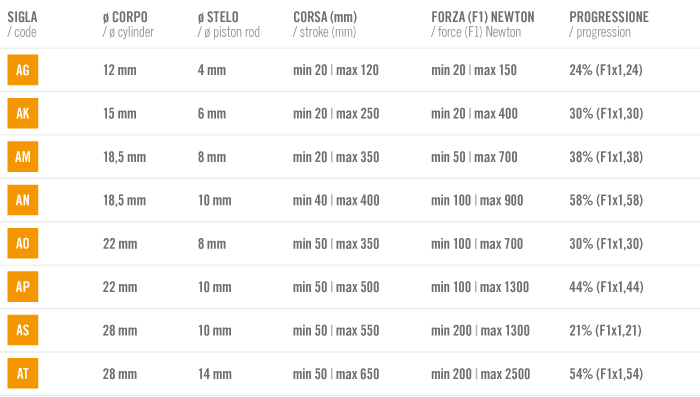

The “198” group refers to the combination between the gas springs cylinder (body) and the piston rod. The most diffused combinations are 15 6; 19 8; 22 10; 28 10; 28 14. Coming back to the example 198 = Cylinder diameter 19 mm. and Piston Rod diameter of 8 mm..

The “600” group refers to the lenght (between holes center or ball joints centers) of the gas spring in the fully opened position. In our example 600 means 600 mm. between holes centers.

The “35” group indicate the force of the gas springs expressed in kilograms. To obtain the newton force multiply it by 10. In our example 35= 35 kg. of force 350N (measured with the piston rod compressed of 10 mm.)

The “Rs/Tz” group identify the code of the attachments. The first indicates the attachment on the cylinder and the second the attachment on the piston rod. In the example Rs2 is the cylinder attachment and TZ is the piston rod attachment:

OTHER EXAMPLE: 15 6. 247.15 – TSNS/TSNS

The code has to be read like: gas springs with a cylinder of 15 mm. diameter and piston rod of 6 mm. diameter. Lenght between holes center of 247 mm. and force of 15 kg. (150N) with TSNS attachment on the cylinder and TSNS on the piston rod.

P.S.: if you are looking for a spare part it is mandatory to communicate the code written on the lable together with the name of the application and the date of production.

Strictly necessary cookies

Strictly necessary cookies

Functionality cookies

Functionality cookies

Tracking cookies

Tracking cookies Targeting and advertising cookies

Targeting and advertising cookies