Gas springs for specific applications Lockable Gas Top

What makes a “Gas Top” gas spring different from traditional gas springs is the presence of a valve in the piston that allows to lock the stroke in any position.

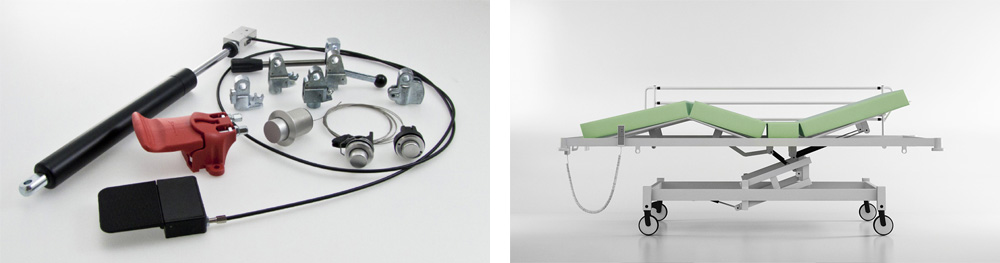

When the lock/unlock pin is pressed the valve opens and the gas spring can be positioned into the desired position. Releasing the pin the stroke will be locked. To activate this pin several devices are used. Most of them use a cable with a lever or button at the end or a direct lever mounted onto the gas springs.

The standard release travel of the pin is 2,5 mm. Other options, available on request, are release travel of 0,5 mm or 3,5 mm. The choice depends on the kind of release device used. Unreleasing button force is in proportion to the F1, F2 of the gas spring combined with the kind of devices used (direct lever, button with cable and so on).

Standard Unrelease force is 25% of F1. In case of high force (F1) or in case of high progression (F2) the unrelease of the valve can be too heavy. Vapsint has a special valve studied for high forces to minimize up to 65% the unreleasing force.

High pressure feature available from 500N.

The lockable gas springs can be produced with the following features.

Elastic locking

The lockable gas spring with elastic locking allows to lock the stroke in any position. Since the piston is locked within an atmosphere of nitrogen (compressible), the block is not rigid, and the result is a “elastic effect” of locking in the direction of traction and compression.

The most common uses of these gas springs are in adjusting arms of hanging wall appliances (like televisions, monitors, etc..), in seats where the effect of suspension is appreciated, in the industrial vehicles to manage the movement of drawers, flaps and so on.

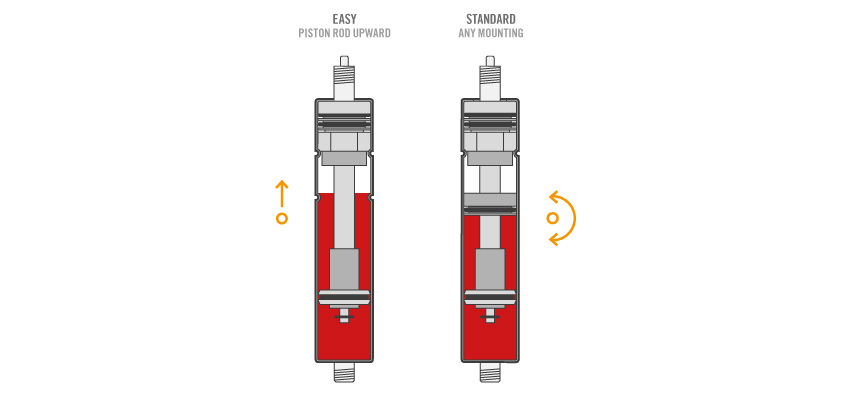

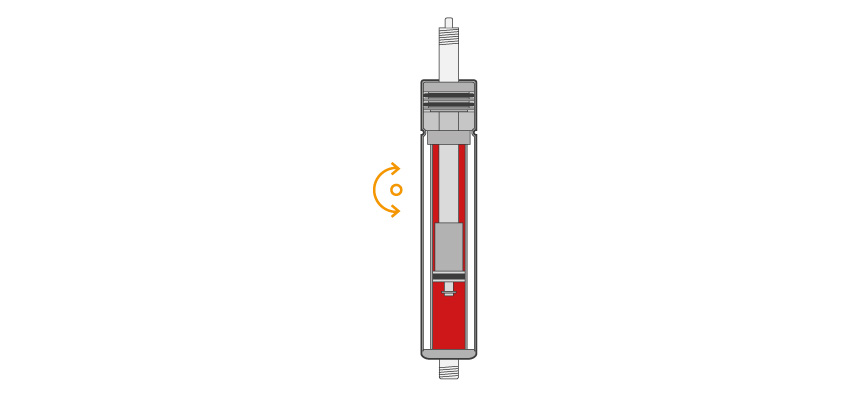

Rigid locking in compression

The lockable gas spring with rigid locking in compression allows to lock the stroke in any position. Unlike the elastic locking the rigid lock is obtained from the movement of the piston inside the oil (incompressible) present in the cylinder. If the oil is between the piston and the bottom of the cylinder, the lock will be rigid in compression.

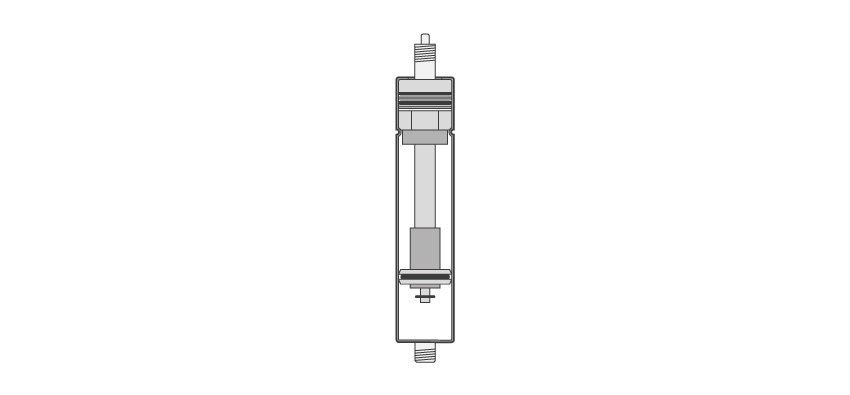

There are two versions of these gas springs that differ in the presence or not of a air/oil splitting piston.

The simpliest version called “easy” (without splitting piston) requires Vertical mounting with the piston rod upward (maximum inclination 30°) .

The version with splitting piston can instead be mounted in any position.

These gas springs found many applications in the medical field such as medical hospital beds, physiotherapy treatment beds, wheelchairs, rehabilitation equipment and in special vehicles (ambulances, fire trucks, etc.).

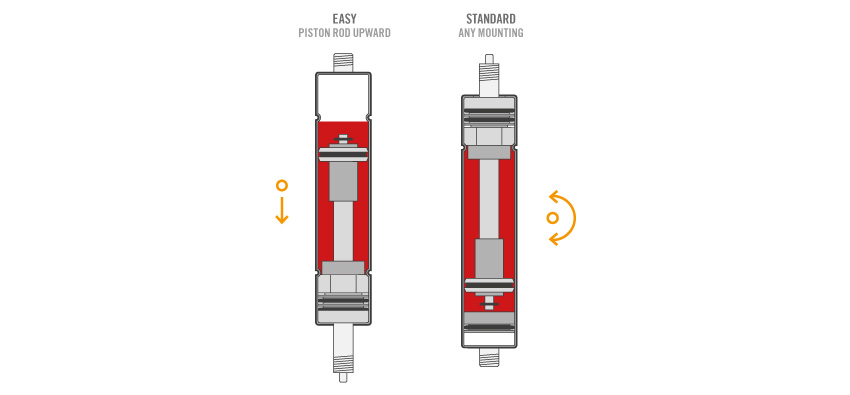

Rigid locking in extension

The lockable gas spring with rigid locking in extension differs from the previous spring with rigid locking in compression for the fact that the oil is situated between the piston and the guide of the cylinder while the nitrogen is in the bottom part of the cylinder.

There are two versions of these gas springs that differ in the presence or not of a air/oil splitting piston.

The simpliest version called “easy” (without splitting piston) requires vertical mounting with the piston rod downward (maximum inclination 30°).

The version with splitting piston can instead be mounted in any position.

The most common uses of these gas springs are in the medical sector where, for the geometry application, the absolute rigidity must be in the direction of the extension of the gas spring. Other applications are in the field of vehicles special, in the industrial sector in general, etc..

Rigid locking with a low progression of force (flat curve)

The rigid locking gas spring with low force progression allows to lock the stroke rigidly in any position. Unlike the other rigid locking gas springs, shows a very limited increase of force F1/F2 (flat curve).

The most common applications are typically present in the furniture industry for the movement of the table columns.

The choice of a “flat curve” is particularly recommended when the application of the gas spring is vertical and the lever arm remains constant throughout the stroke.

Area of applicability

- Car seats

- Vehicles steering gear

- Hospital furniture

- Wheelchairs

- Therapy beds

- Office furniture

- Table column

Features

- Lockable Gas Springs

- Stainless Steel AISI316L Lockable Gas Springs

Strictly necessary cookies

Strictly necessary cookies

Functionality cookies

Functionality cookies

Tracking cookies

Tracking cookies Targeting and advertising cookies

Targeting and advertising cookies